Thermoforming film, is also known as lidding film and base film.

lidding film, top film;

bottom film, base film

Thermoforming Film for Packing Meat

Thermoforming is based on the property of plastic materials to become stretchable when heated but regain strength and rigidity when cooled. It is fed intermittently into a die and heated until it turns soft. Then it is formed against the die bottom. Compressed air or vacuum are used to push or suck the film into the die.

Thermoforming top and bottom films are mostly used for high-speed automatic forming lines such Multivac and ULMA etc, which can improve packaging efficiency greatly. Forming films are easy to pack large size and irregular shape products, like meat products, cheese, vegetables, bakery products and semi-finished food.

Finefood forming films offer reliable barrier properties to maintain your products fresh flavor, texture & appearance throughout its entire shelf life.

Material And Structure:

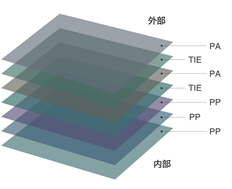

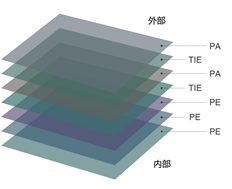

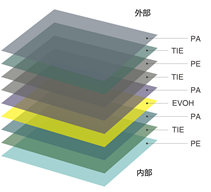

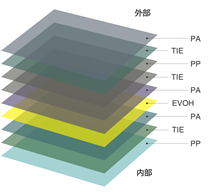

The stretch film is composed of PA, PE, PP, EVOH and other materials, Made by multi-layer co-extrusion under blowing water cold blowing film. Thermoforming films have two types: 7 layers and 9 layers.

7 layers Structure: PA/TIE/PA/TIE/PE/PE/PE;PA: 25%-30%。

9 layers Structure: PA/TIE/PE/TIE/PA/EVOH/PA/TIE/PE;

PA Proportion: 25%-30%, EVOH proportion: 6~12%, customized.

Product Form and Common Specification

Thermoforming film Width Range: 60mm-1300mm;

Common top Film width: 396mm,406mm,520mm;

Common bottom Film width: 423mm;523mm。

Thickness Range: 70μm-280μm;

Common Thickness: 100μm,120μm, 140μm,150μm,175μm,200μm,235μm.

Forming Film Features:

|

FinePack can do customized according to customers' specific requirements, including dimensions, printing, etc. With five down-blowing film machines, Finefood produce 100mt per day, and exported to North America and Europe, such Canada, North America, Mexican, the UK, Germany and so on.

Contact: Sophia

Phone: +86 159 51203568

Tel: +86 519 88388390

Email: finepack.matl@gmail.com

Add: 7 Kaicheng RD, Industria Zone, Suzhou,Jiangsu, CN.